Expertise and Knowledge

Brotec’s plastic extrusion capabilities and processes allow us to manufacture some of the highest quality plastic tubing and piping products to be found in Australia. Made to withstand harsh Australian conditions and meet industry standards, our plastic tubes are both adaptable and flexible.

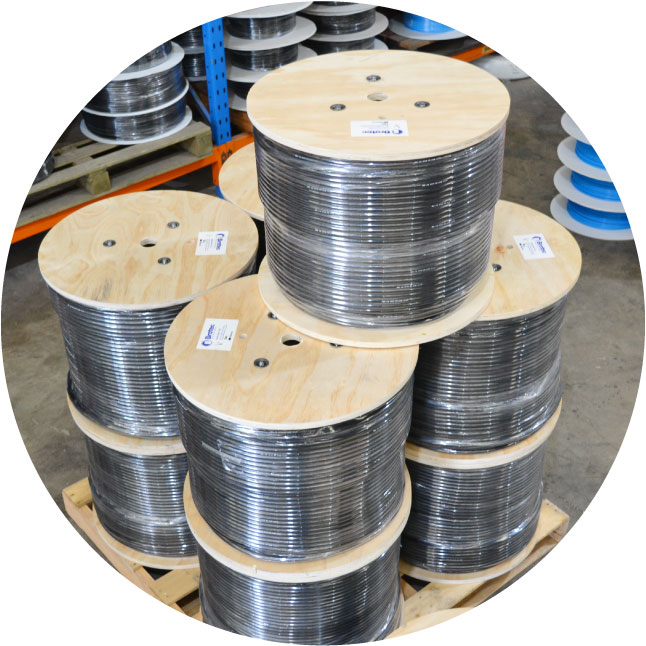

For Jobs Big and Small

As a leading plastic extrusion company our capabilities include the ability to handle large scale orders and provide tailored solutions. Brotec specialise in the smaller size range for pneumatics and we are tooled to manufacture up to 38mm outside diameter pipe and tubing. But such is our array of standard and custom sized nylon and polyethylene tubing and piping, we’re confident that we can meet your application requirements.

Customer Service

Enquiries are dealt with by a passionate and technically experienced team with many years of Nylon extrusion experience. You’ll talk to experienced people making informed decisions, not sales people or order talkers.

Proven Reliability

Our experienced team will always give clients realistic lead times and accurate delivery schedules. Open, honest communication with our clients means they are always aware of delivery times.

Tailored Solutions

Manufacturing a large range of industry standard tubing isn’t the end of the story. If your requirements are specific, Brotec can work with you in developing and manufacturing tubing to fill your specific requirements.